Project Description

CANADIAN STEAMSHIP LINE

Vessel: M/V NANTICOKE

Self-unloading bulk carrier

Systems:

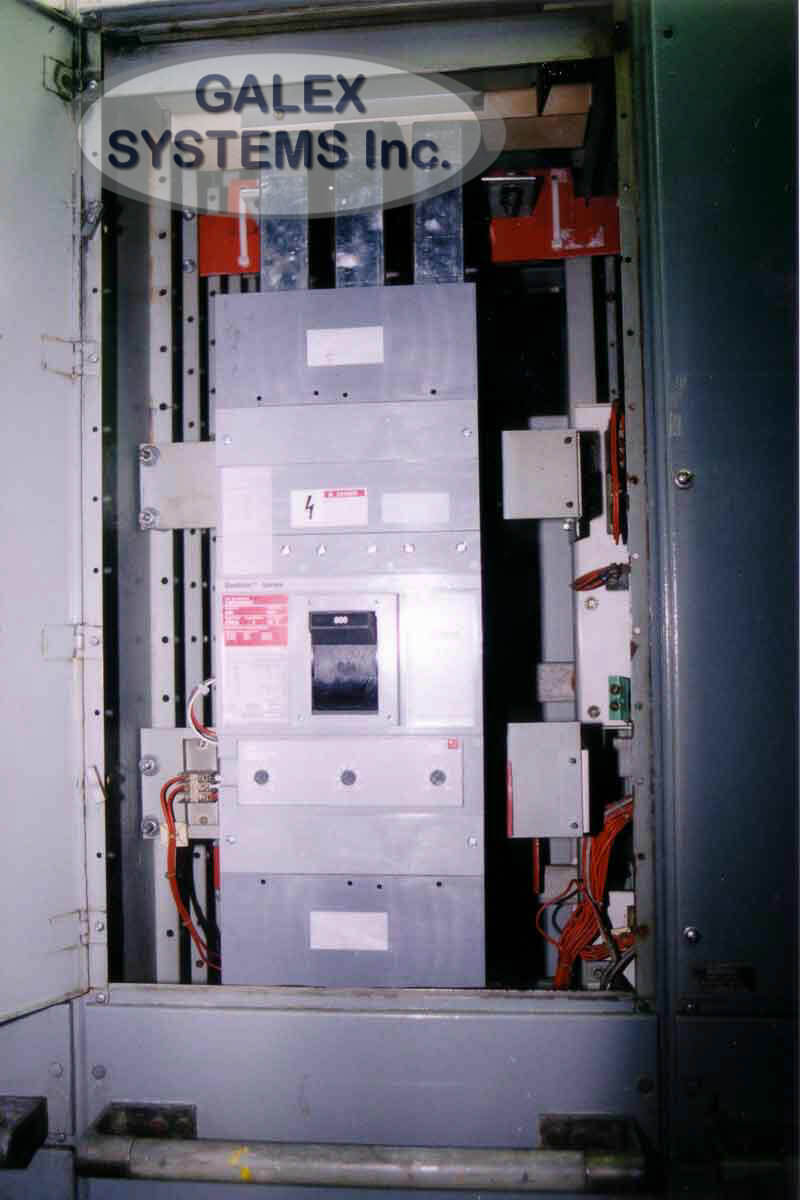

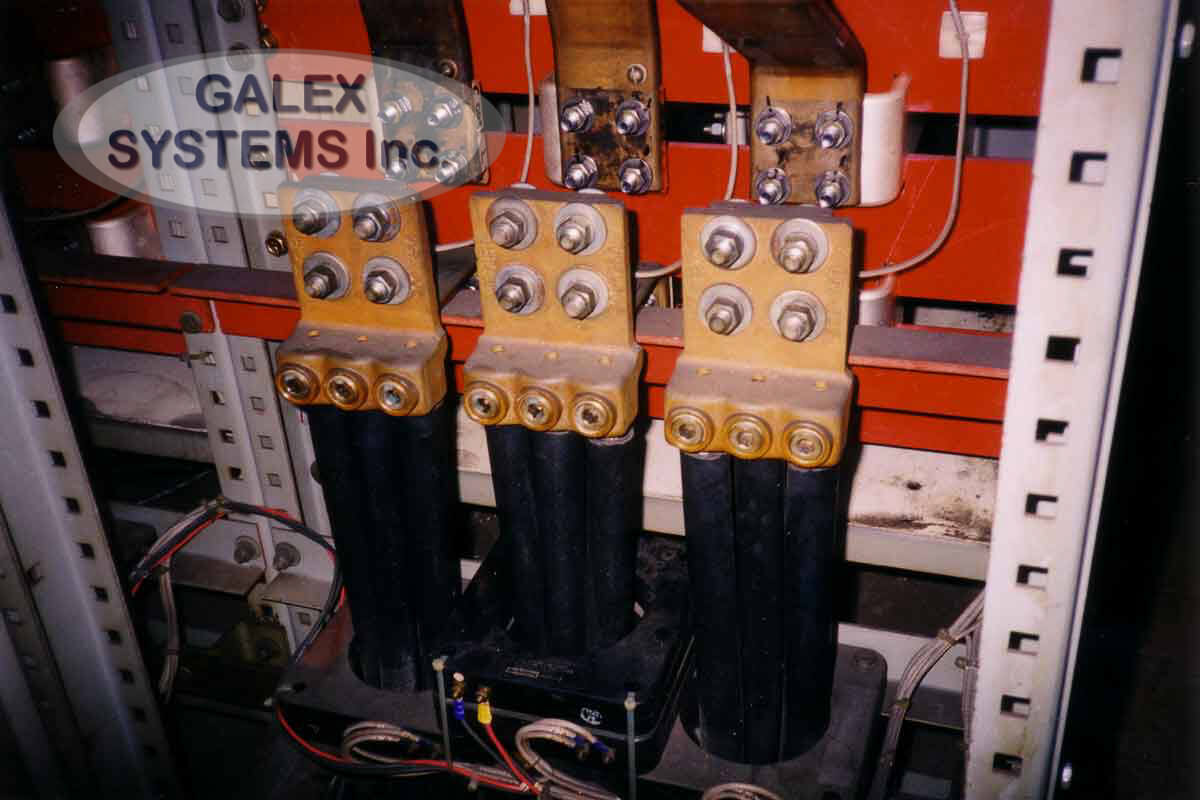

The Main Switchboard of this diesel propulsion vessel was refitted, new air-circuit breakers and controls were added. New Power Generation Control was implemented, based on Siemens S7-PLC.

New PLC based Shut-Down system for the propulsion engines was installed. The Service MCC and unloading MCC were upgraded with new air-circuit breakers, molded circuit breakers and controls. New Air Compressor Automation was implemented into the Alarm and Monitoring System.

Equipment supplied/refurbished:

- Main Switchboard,

- Shore Power Connection,

- Power Generation Control,

- Service and unloading MCC’s,

- Shut-Down System.

- Air Compressor Automation Panel

Engineering services provided:

Mechanical and Electrical Engineering, Mechanical and electrical design and drafting for:

- Generation control system,

- Upgrading the Main Switchboard,

- Alarm and Monitoring System upgrade,

- Engineering for Breakers Changing and Updating Controls,

- Air Compressor Automation.

Project Management:

- Turnkey project for :

- Main Switchboard,

- Shore Power Connection,

- Shut-Down System.

- Air Compressor Automation

Installation, Manufacturing and Commissioning:

Complete rewiring of Main Switchboard, Shore Power Connection. Installation of the Shut-Down System and updating of the Service Motor Control Centers.

Technical documentation:

Main Switchboard, Shut-Down System, Distribution network, Air Compressor Automation – Complet documentation Package

2000-2002, Lesmechins Que., Montreal Que.